Guide to Increasing Lifetime of Precision Rotary Indexer

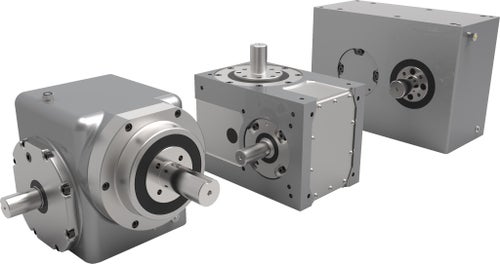

Rotary Indexers consists of precision parts providing smooth and precise motion for various applications. Post rated lifetime of precision Indexers performance of the indexer may start degrading and there could be potential system failures due to wear and tear of parts. In this blog post, we will discuss key indicators that will help you determine when it's time to replace critical parts in your indexer, promoting optimal functionality and preventing expensive downtime.

- Irregular or Inconsistent Motion: If you notice jerky or uneven movement, loss of positional accuracy it could indicate wear/damage to the critical internal parts. Over time, the rolling contact surfaces of the CAM followers wear out, compromising the smoothness and accuracy of the indexing motion. One of the primary signs that cam followers may need replacement is irregular or inconsistent motion within the indexer.

- Excessive Noise or Vibration: Unusual noise or excessive vibration during the operation of your indexer could be a clear indication of damage to internal parts. Worn or misaligned CAM followers can cause increased friction with partnering components, resulting in noise and vibration. These issues can negatively impact the overall performance of the indexer and potentially lead irreparable damage if left unaddressed. Damaged CAM, output bearings, input bearings may also be the reason for Noise and vibration. Careful assessment from experienced technician is required.

- Signs of Wear: Loss of preload in the stations is primary indication of indexer failure.

- Increased Operating Temperature: If you notice that the operating temperature of your indexer is consistently higher than normal, it could indicate severe wear of internal critical parts. Worn or damaged cam followers can generate increased friction and may result in damage of the CAM, leading to higher operating temperatures. Monitoring the temperature and comparing it against recommended guidelines can help determine if critical parts are functioning as normal.

- Lubrication Requirements: Precision parts require clean, recommended grade lubricant to operate smoothly and reduce friction. However, if lubricant degradation is occurring quickly than recommended guidelines, it could be a sign of excessive wear. This requires examination of indexers by experienced technician and if it is not field repairable unit needs to be rebuilt.

Periodic inspection, maintenance and assessment of Indexers are vital for ensuring the optimal performance and longevity of your indexer. By monitoring motion irregularities, excessive noise or vibration, attention to visible signs of wear, increased operating temperature, and lubrication requirements, you can determine when it's time to overhaul the indexers. Timely maintenance reduces the risk of unexpected failures, minimizes downtime, and helps maintain the efficiency and reliability of your indexer. Remember, investing in superior quality indexer manufacturers like DESTACO-Camco and adhering to a proactive maintenance schedule will extend the life of your indexer and enhance your industrial processes. Primary expectation here is that Rotary indexers must be used at the same parameters of application sizing data sheet to meet the rated lifetime.