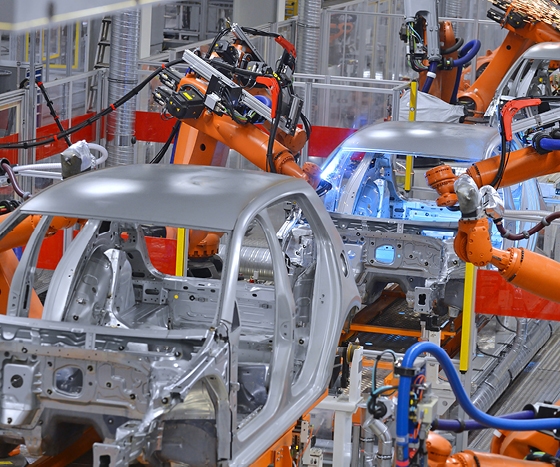

Types of Hot Stamping Ovens

There are two types of hot stamping ovens: Soak Oven and Stack Oven. We grab the blank and place it into a soak oven where conveyors moves parts and increase the parts' temperatures, and then our grippers place them into a die for stamping. For the inside die, fluid cools the item before coming out.

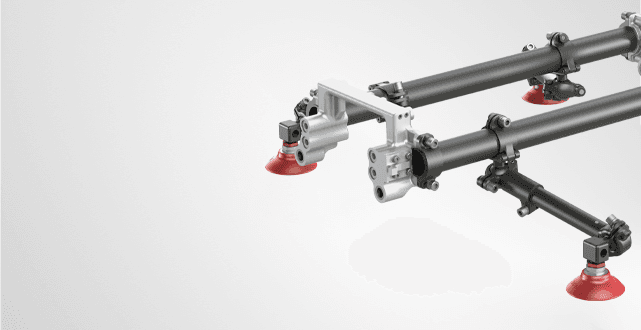

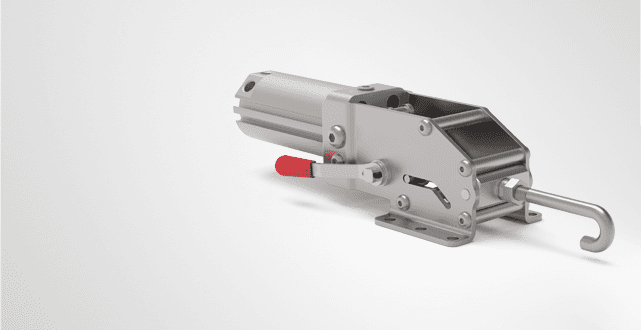

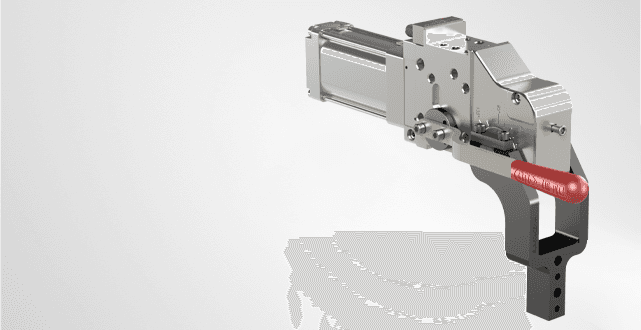

DESTACO's End Effectors are designed and built to touch, hold and handle the steel and/or aluminum that can be inserted or placed in various types of hot stamping ovens or furnaces, heating the material in excess of 900 degrees C. and also to retrieve the hot stamped parts from the ovens and place them where needed.