DESTACO'S CUSTOM SOLUTION REDUCES WEIGHT

Brand Pillar: Focused

Industry: Hot Forming

Product Lines: End Effectors

CHALLENGE

In the hot stamping process using stack ovens, the robotic end-of-arm tools need to go into a 950°C oven to drop off cold parts and pick up hot parts, once they reach temperature, to load the stamping press.

The process currently employs a completely fabricated end-of-arm tool made from stainless steel sheet formed into square tubing and stitch welded with a mig process. The part-touching and rotating clamp shafts are made from a different grade of stainless steel.

There are multiple problems with this type of construction:

- Based on the fabricated construction of the square tube, reinforcements are required to increase the stiffness, adding additional weight. This additional weight causes the tool to bounce while in motion and creates a problem picking up the part and dropping off.

- With the two grades of material, the thermal expansion and contraction are different causing the clamping fingers to loosen and require adjustment.

- The fingers are attached using standard cap screws that will expand or contract during the heating and cooling process, with the potential to loosen or fall out completely. If the finger components loosen, they can fall into the die and cause major damage.

SOLUTION

After listening to three separate customers with similar issues, DESTACO designed a custom solution to solve their issues.

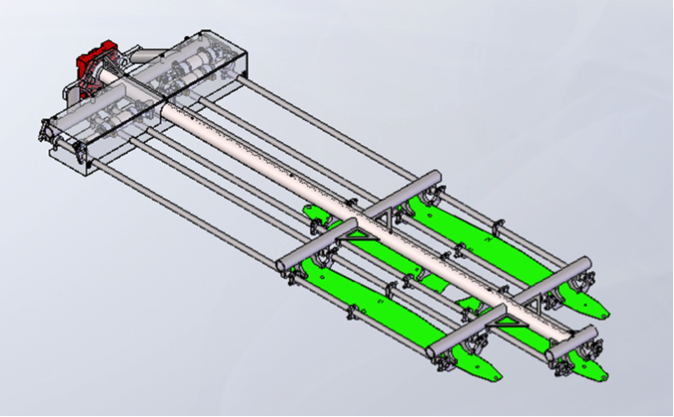

- The unique tool design uses schedule 40 stainless pipe and the main backbone is trussed. This construction is extremely rigid, lighter weight (as much as a 20% weight savings) and the strength to weight ratio is better than the supported square tuning. The trussed construction greatly reduces the tool bounce during movement and through the heat and cool down cycles.

- The steel is the same grade for the entire tool to keep the thermal properties the same. Though the material thickness varies, the material density is the same.

- To resolve the loose fingers issue we used a friction coating on the clamping surface that increases the friction by 50%. We used high temperature screws, rated for 1300°F, so the screws do not expand and contract as standard cap screws do.

RESULTS

![]()

The reduced weight and the truss-type structure greatly reduced the bounce or shake during the load and unload cycles. Because of the better thermal properties, they no longer need to touch up the robot program during long cycle runs.With the addition of the high temperature screws and the surface coating on the fingers they have not experienced the fingers coming loose.

The reduced weight and the truss-type structure greatly reduced the bounce or shake during the load and unload cycles.

Because of the better thermal properties, they no longer need to touch up the robot program during long cycle runs.

With the addition of the high temperature screws and the surface coating on the fingers they have not experienced the fingers coming loose.