End Effector Operating Parameters In Metal Stamping

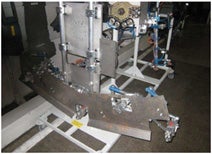

Robotic end of arm tooling (EOAT), also known as “end effectors,” plays an important role in ensuring the efficiency and accuracy of many critical pick-and-place and workholding applications in the metal-stamping and metal-assembly industries.

Press Shop & Body Shop Environments

Generally, these activities take place in one of two operating environments:

- Press Shop - The press shop is where traditional part-stamping processes are performed, though the definition of the press shop has evolved in recent years. Old-school press shops utilize a linear “transfer press” operation that relies on non-robotic automation. However, more press shops are beginning to incorporate “tandem” lines in their facilities that use robots to perform various functions that used to be completed manually. Therefore, the end effectors in a tandem line need to be compatible for use with robots or the increasingly popular collaborative “cobot” applications where a human technician works side-by-side with a robot.

- Body Shop - In the body shop, parts that have already been stamped are married together via welding, gluing, etc. The body shop is a robot-reliant facility, with modular end-effector systems developed to meet the needs of the specific applications, most of which require the precise positioning and holding of parts.

WITH THE OPERATING ENVIRONMENTS DEFINED, THE AUTOMATION SYSTEM CAN NOW BE OUTFITTED WITH END EFFECTORS.

Three Operating Parameters to Assess

In this regard, there are three major operating parameters that must be assessed and quantified before the proper end effector can be selected:

- Cycle Time - Actual cycle time will differ based on the operating environment. In Press Rooms, it is measured in strokes per minute (spm), which is the number of parts stamped per minute. In the Body Shop, cycle time is the movement or operations the end-effector system can perform to complete a part. Advances in digital-design and simulation capabilities can allow end-effector designers to perform interference studies, which can point out potential bottlenecks in the part-moving process. These bottlenecks can then be designed out of the system before it becomes active, which helps optimize cycle time.efficient throughput.

- Weight - Part weight is a huge determining factor in the type of end effectors that can be used. It is important that the designer of the EOAT understands that the tooling must be as robust and lightweight as possible so it can perform reliably, with no drops, vibrations or misplacements. It must also be able to handle many thousands of transfer cycles without fatiguing or breaking down.

- Reach - How far the EOAT will have to extend to perform its required job also plays a role in determining which end-effector solution is best for the job. It’s best when the robot can reach or travel as much of the required distance as possible. The idea here is to limit the amount of offset load and/or weight that is being placed on the EOAT. Keeping the EOAT as small (minimum offset load) as possible will also help reduce deflection, resulting in a better automation cadence and more efficient throughput.

Contact our experts to share your application goals and technical specification today!

Back to Top