What To Know About Manual, Quick-action Toggle Clamps

WORKHOLDING PRODUCTS FOR YOUR INDUSTRY & MANUFACTURING PROCESSES

DESTACO has been the leader in workholding products since first inventing the toggle clamp in 1936. Since then, we have maintained the largest selection of manual, hydraulic and pneumatic components on the market. Whatever the size or scope of your application, DESTACO offers the perfect solution to your specific needs. This guide details what you need to know to make an informed decision about whether manual quick-action toggle clamps are right for your application, as well as their features and benefits. Contact our clamping experts to learn more!

Know Your Clamping Requirements & Applications

Workpieces need to be held in a specific position using a specific amount of force in the shortest period of time. Once the workpiece is clamped, the processing of it is usually carried out. This means that the following tasks must be fulfilled using clamping products:

- Quick clamping

- Secure holding

- High clamping forces in a variety of space requirements

- Distortion-free clamping of the workpiece

- Good accessibility to the workpiece

Workpieces are clamped in nearly all applications of a manufacturing environment. In the metalworking industry, reliable clamping is a basic requirement for drilling, welding, bending, grinding, testing, assembling, etc. Additional applications that use Destaco clamping products:

- Automobile industry

- Electrical industry

- Woodworking industry

- Plastics industry

- Textile industry

- Chemical industry

- Food industry

How Toggle Action Works

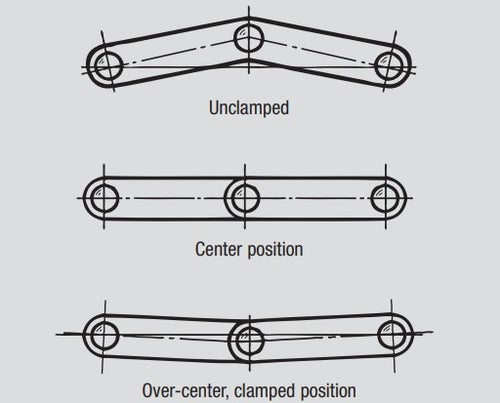

Toggle action clamps operate through a linkage system of levers and pivots. The fixed-length levers, connected by pivot pins, supply the action and clamping force. Toggle action has an over-center lock point which is a fixed stop and linkage. Once in the over-center position, the clamp cannot move or unlock unless the linkage is moved. All types of toggle clamps have this same action, just oriented differently.

How Toggle Action Force Factors Function

The maximum clamping or exerting force developed in any toggle action clamp is attained when the three pivot points of the mechanism are in a straight line. While this is theoretically true, it makes no allowance for vibration and intermittent load conditions found in industrial applications. Such conditions would soon unlock an improperly designed clamp. The proper amount of over-center travel to produce maximum holding force and yet ensure positive locking is a carefully calculated and controlled dimension developed by years of experimentation and experience.

Each clamp is rated with its “holding capacity.” This is the maximum load or force the clamp will sustain in the closed and locked position without permanent deflection. Exerting forces applied as the clamp closes are less than the holding capacity, and are dependent on variables such as the position of the operator’s hand on the handle; amount of force applied; and position of the spindle on the bar.

Toggle Action Clamps Compared With Cam Action Clamps

Cam action uses frictional force to effect a locking condition between the cam surface on the bar and the follower on the handle. Toggle action clamps have many advantages over cam action clamps, mainly because cam action clamps allow some movement while clamping. Toggle action clamps thus provide a more consistent clamping point, can be manufactured from inexpensive materials, and are available in stainless steel for outdoor or corrosive applications. If the material being clamped has a variable thickness, however, a cam action clamp has the ability to better accommodate this application.

What About "Exerting/Clamping Force" & "Holding Capacity"?

In the case of clamping products, a clear distinction must be made between exerting forces and holding capacities. Here are the essential features.

Exerting or Clamping Force

The “exerting force” of our air toggle clamps is well defined. Manually operated clamps present a series of variables to determine actual exerting force.

These variables are:

- the force exerted on the handle by the operator;

- the point on the handle where this force is applied;

- the mechanical advantage in the linkage; and

- the point on the work holding bar where the force will be measured. As a general rule, the mechanical advantage available throughout the line ranges from 2:1 to 10:1

Holding Capacity

The “holding capacity” of Destaco toggle clamps has been determined by actual tests. It is defined as the maximum amount of force which may be applied to the work holding bar, in the closed position, without creating permanent deformation of the clamp components. This maximum force is measured at a point closest to the base and diminishes as the spindle approaches the end of the bar. The ratings for holding capacity are maximum and should not be exceeded. These values include a safety factor.

Contact us today to share your application goals with our team of experts, browse our manual clamping products, or learn how to calculate exerting/clamping force and/or holding capacity!